Airport and Aviation Maintenance Waste Incineration Solutions

Airport and Aviation Maintenance Waste Incineration Solutions

Airports and aviation maintenance bases generate diverse waste streams requiring strict environmental and safety controls. HICLOVER provides fixed dual-chamber incinerators with integrated flue gas washing systems, designed to meet civil aviation fire protection standards while ensuring efficient destruction of oil-based and organic waste.

Aviation and Airport Waste Characteristics

Within airport maintenance zones, aircraft hangars, medical first-aid stations, and catering centers, the daily waste mix typically includes:

-

Oil filters, used lubricants, and contaminated absorbents from maintenance operations.

-

Food residues and packaging from airline catering centers.

-

Medical and sanitary waste from airport clinics.

Such waste streams are difficult to manage using conventional disposal due to contamination with hydrocarbons, grease, and biological materials. Controlled high-temperature incineration above 1100°C ensures total destruction of pathogens and hydrocarbons, reducing emissions to safe levels.

HICLOVER System Design

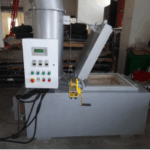

HICLOVER’s fixed dual-chamber incinerator configuration separates the primary combustion zone from the secondary post-combustion chamber.

-

Primary chamber: directly burns mixed solid waste, maintaining stable combustion.

-

Secondary chamber: oxidizes unburned gases, achieving complete combustion and odor control.

-

Flue gas treatment: optional wet scrubber or alkali tower neutralizes acid gases before release.

-

Automation: PLC control with temperature sensors and interlocks ensures stable operation and safe shutdown.

This structure complies with international civil aviation and environmental emission guidelines, minimizing smoke and odor near terminals and runways.

Environmental and Operational Benefits

-

Reduces waste volume by up to 95%, minimizing off-site transport.

-

Handles mixed solid and semi-solid waste, including oil residues.

-

Suitable for on-site treatment within airport maintenance or logistics areas.

-

Scalable capacity options: from 50 kg/h for small terminals to 300 kg/h for regional aviation hubs.

-

Optional diesel or natural gas burners (Riello or Italy-brand) provide reliable ignition.

Global Relevance

Airports in Africa, the Middle East, and Southeast Asia are increasingly prioritizing sustainable waste management to meet ICAO and WHO standards. HICLOVER systems align with these global objectives through containerized or fixed installations adaptable to local regulations and site constraints.

For example, smaller regional airports in East Africa or Pacific islands benefit from containerized dual-chamber incinerators, which can be shipped and installed rapidly with minimal civil works. Major international airports near coastal zones prefer fixed concrete-base models with corrosion-resistant chimneys and integrated quench towers.

Integration with HICLOVER Technologies

Learn more about HICLOVER’s industrial and medical incineration systems and accessories:

Conclusion

As aviation operations expand globally, efficient and compliant waste disposal becomes critical. HICLOVER’s airport and aviation maintenance incinerator systems provide a proven solution for managing mixed industrial and biological waste safely, protecting both airport personnel and the surrounding environmental quality.

2025-11-09/19:58:46

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker Protection |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature Protection |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic Protection Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |